Why choose Leitech?

System Leitech eliminates the classic tool combination of a traditional thread gauge and a caliper. System Leitech also eliminates the need of a traditional gauge with step marking. In one single operation, System Leitech offers the measuring of the internal thread tolerance and the measuring of the thread depth.

Do you wish to:

- use high-end specialized products for internal thread control?

- raise your level of quality?

- have a flawless measuring method?

- contribute to lower costs in your company by:

- reducing your control time?

- reducing the number of needed thread gauges?

- reducing your machine hours and your tool consumption?

System Leitech is your solution!

Leitech Instruments operates with the latest technology and is always fully updated with regard to production and process technology. We bring our 30 years of product knowledge to your disposal in all types of approaches:

- at the very beginning of the project phase

- through the project phase

- prototypes

- special projects

- customized solutions

Our company has more than 30 years of experience in the industry. This is particularly interesting when dealing with unique projects, which require specially adapted tools.

System Leitech has become the preferred tool for a large number of leading companies worldwide.

Reduce your number of gauges by 72%

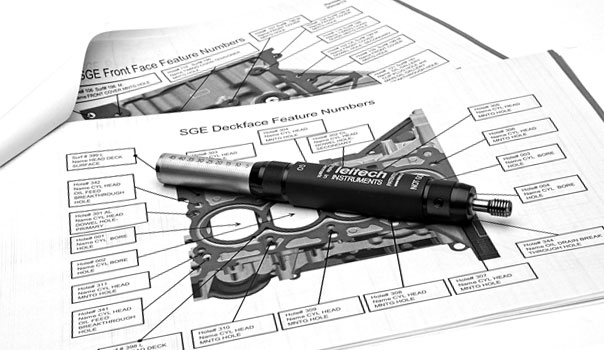

Just 7 Leitech Combi Gauges are needed on an American automotive plant for the overall control of a 4-cylinder, 16-valve engine with 103 threaded holes.

An industry using conventional gauges normally requires individual gauges for the inspection of each thread-hole depth. This means that it is necessary to work with a large number of different gauges. However, a high number of gauges mean unnecessary costs for the gauge stock and an increased risk of human error.

As one Leitech Combi Gauge can measure all thread depths within its range, the number of gauges can be reduced considerably when System Leitech is introduced. Often a single Leitech gauge can replace several different conventional gauges with filed notches indicating minimum thread depth. This results in less capital tied up in gauges and fewer human errors. By using the System Leitech you also might find considerable savings in technical drawings, quality documentation, and calibration of gauges.

Reduce Quality Control Time by 45%

The Leitech Combi Gauge allows you to check your GO thread size and depth of a threaded hole - all in one fast and cost-effective operation. The measuring sleeve allows direct reading of the depth when the gauge is fully inserted into a thread hole.

In a V12 engine block from one of Europe's leading car manufacturers, 99 threaded holes in 4 thread sizes were measured and inspected for tolerance and depth.

Using conventional gauges the inspection time was 71 minutes.

Using the Leitech Combi Gauges the inspection time was 39 minutes.

The difference represents a reduction of 45% in time consumption. The precision of System Leitech and the direct reading made it possible to meet increased quality demands.

Save 17% on Machine Hours and Tool Consumption

Companies are creating additional expenses when drilling and tapping large quantities of threaded holes 15% to 40% deeper than necessary to meet depth requirements! Tool wear and machine hours increase dramatically.

If your company produces 1,000 holes per day, and if - for good measure - they are just 1,7mm too deep, this means that in a year a surplus of 374 meters of thread is cut. How much does 374 meters of thread cost?

The System Leitech allows your machinist to adjust drilling and tapping depths precisely at set-up time. In addition the operator can monitor this depth as the parts are produced.